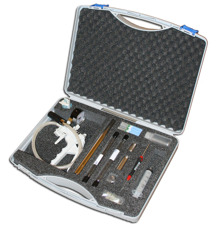

BAT Permeameter (#3-300)

The BAT Permeameter combines with the BAT Piezometer equipment and the BAT MkIII Filter tip. With the BAT Permeameter accurate and high precision in-situ permeability tests can be performed.

Test assembly

The BAT Permeameter incorporates a Test container. The container is sealed in both ends with a flexible septum.

At its lower end the Test container temporarily connects with the BAT MkIII Filter Tip, using a double-ended injection needle. At its upper end the Test container interconnects with the BAT Sensor, also by using an injection needle. Thus making possible measurement of the pressure, P, inside the Test container.

Conducting a permeability test

The BAT Permeability test is based on measurement of the rate of flow into or out of the Test container. This rate is computed by measuring the pressure change in the Test container, which by using Boyle´s law can be translated into a volume change. Analysis of the time-pressure record thus yields the coefficient of permeability, k.

Automatic testing procedure and easy calculation of k – values

By using the logging function of the BAT Sensor, pressure data are collected automatically at a preselected time-interval.

The time - pressure record can be fed directly into a portable computer for an immediate field calculation of the coefficient of permeability, the k –value.

Typical testing time for different k-values:

k » 10-7 m/s : 1 minute

k » 10-8 m/s : 10 minutes

k » 10-9 m/s : 1 hour

k » 10-10 m/s : 10 hours

Vadose zone / Clay liner testing

The BAT Permeameter combined with the BAT MkIII Vadose Filter Tip enables

permeability testing in the unsaturated zone. A typical application is testing of the permeability of compacted clay liners. Depending on the soil charachteristics, the BAT Filter Tip can be installed as shallow as 0.10m.

- BAT Permeameter manual.pdf 1.5 MB